1 / 3

1 / 3Vision-based handling of lids with igus ReBeL Cobot

Hardware Price:

DOF

6

Max. payload

2

kg

Max. reach

660

mm

Automated Lid Handling with igus ReBeL and ifm Sensor: Precision and Efficiency

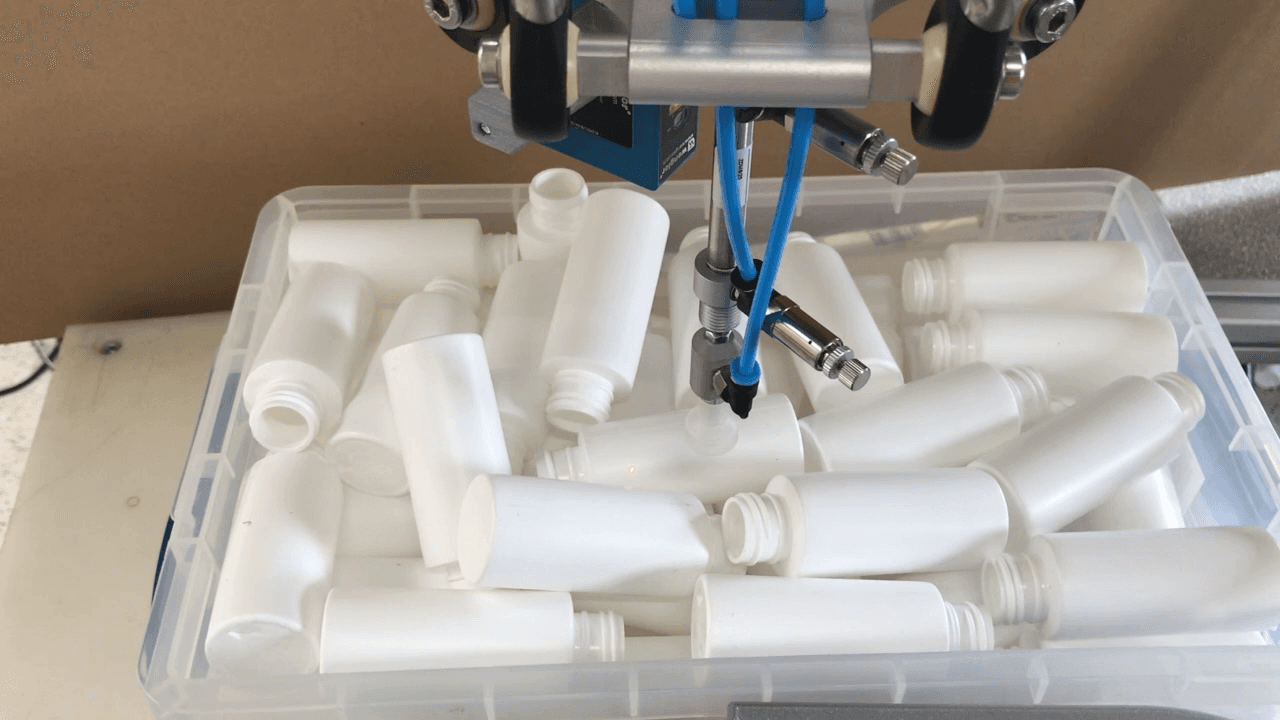

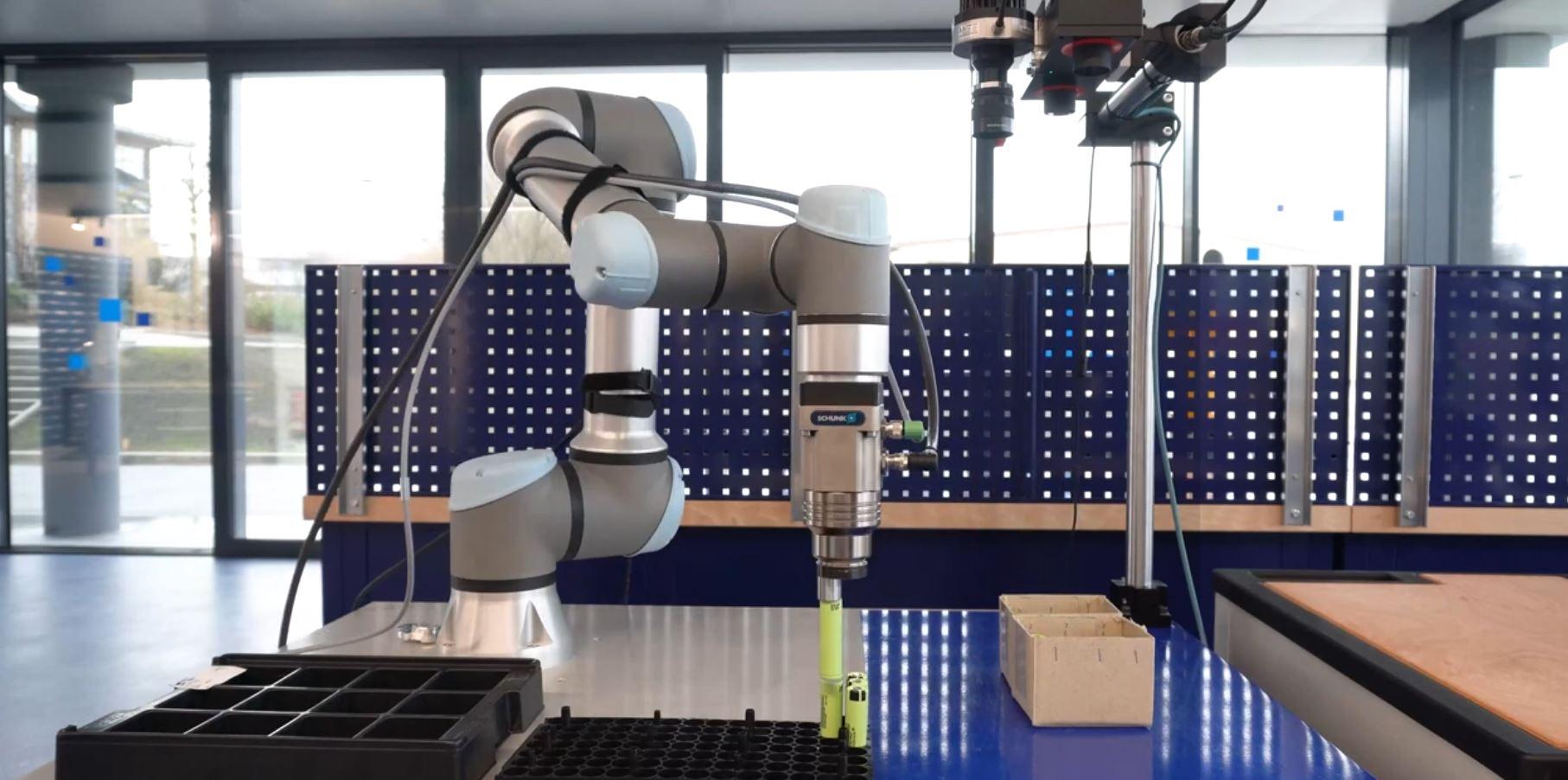

Efficient pick-and-place operations require accuracy, speed, and seamless communication between components. This advanced system utilizes the igus ReBeL 6DOF robotic arm, equipped with a suction gripper, alongside an ifm sensor and camera for object recognition. These technologies work together to identify lid positions and control precise movements, delivering reliable and optimized performance for automated handling tasks.

What is the Application?

The system automates pick-and-place tasks for lids, using advanced sensors and cameras to identify and securely position objects with precision.

What are the Advantages of the Solution?

Enhanced Accuracy: Sensor-driven object recognition ensures precise lid positioning.

High Speed: Effortlessly handles fast-paced pick-and-place operations.

Intuitive Control: The user-friendly software simplifies robot programming and operation.

What are the Advantages of the Robot?

The igus ReBeL 6DOF robotic arm offers advanced features for precise handling:

Flexibility: Six degrees of freedom enable versatile movements.

Reliable Gripping: Suction gripper ensures secure and consistent object handling.

Seamless Integration: Communicates effectively with sensors and software interfaces.

Streamlining Pick-and-Place Operations with Advanced Automation

This system combines the igus ReBeL robotic arm, ifm sensor, and camera to deliver fast, accurate, and reliable automated lid handling. With its ability to perform repeatable tasks efficiently, it provides an ideal solution for industries demanding precision and high-speed performance in pick-and-place processes.

5 Components